1. Basis for Design Standards

The IEC60884-1 standard sets out detailed specifications for the general requirements of plugs and sockets for household and similar purposes. Among them, for the performance testing of products in terms of withstanding pressure, specific test methods and indicators are stipulated. The heat compression test device is carefully built to meet these standard requirements. For example, in accordance with the provisions of Clause 24.5 and related diagrams in the standard, the parameters and test procedures of the heat compression test device are accurately set to ensure that the test results can accurately reflect whether the product meets the standards. At the same time, it also complies with relevant domestic standards such as GB2099.1-2008, ensuring product quality under both international and domestic standard systems.

2. Test Principle:

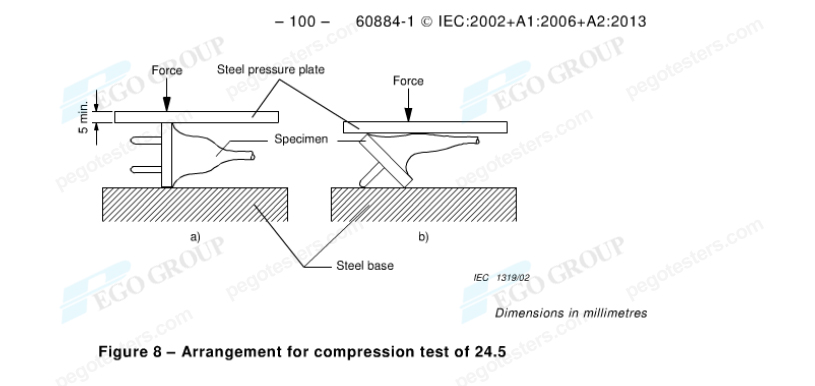

During testing, place electrical accessories under test—like plugs, sockets, mobile socket covers, and surface – mounted boxes—between the moving and fixed pressure blocks. First, the moving block descends using weight gravity to apply pressure to the sample. Then, the cylindrical surface of the block evenly transmits this pressure, simulating real – world usage pressures. For instance, when testing a plug’s mechanical strength, follow standard requirements: at 23±2°C, position the plug between the plates. Next, apply 150N or 300N of pressure via the block, holding it for 1 minute at two specified positions (e.g., positions a and b in IEC60884 – 1 Figure 8). This checks if the plug resists damage or deformation, ensuring safe real – world use.

3. Applicable Scenarios:

The heat compression test device is suitable for mechanical strength testing of electrical accessories such as power plugs and sockets to ensure they do not cause electric shock or structural damage under pressure.

4. Operation

4.1 Test Preparation Stage:

First, check whether all parts of the compression test device are intact. Then, ensure that the moving pressure block can move freely and smoothly on the guide rail bracket, and the weight of the weights is accurate and undamaged. Next, according to the test requirements, place the device on a test bench with stable temperature at 23±2°C. At the same time, prepare the test plug, ensuring that the sample surfaces are clean, undamaged, and meet the test requirements.

4.2 Sample Installation and Pressure Application Stage:

Rotate the handle to lift the weight, place the specimen directly under the steel pressure block as shown in below figure 8 a), rotate the handle to lower the weight, make the specimen bear 300N force for 1min.

4.3 Test Result Judgment Stage:

After applying the pressure and reaching the specified time 1min, take out the sample. Check it within 15 minutes after taking it out. If there is no standard-defined damage, such as shell rupture, pin deformation, etc., the plug is judged to pass the mechanical strength test.

The IEC60884-1 heat compression test device strictly follows standard designs. Moreover, its structural composition is reasonable, its working principle accurate, and its technical parameters detailed. Additionally, it adheres to standardized operating procedures. As a result, it reliably guarantees quality inspections for electrical accessories and other products, and plays an indispensable role in ensuring product quality and safety.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.