Polymeric materials such as plastics, rubbers, and fabrics permeate daily life and industrial production—from small mobile phone charger casings to large-scale automotive interiors and building insulation materials. If these materials fail to meet flame retardancy standards, they can easily ignite and spread when exposed to open flames or high-temperature heat sources, even producing toxic fumes and molten drippings that significantly intensify fire hazards. To accurately evaluate materials’ resistance to combustion, the Vertical Burning Test and Horizontal Burning Test were developed. Acting as two professional “safety guardians,” they simulate risks for different combustion scenarios, building a critical defense line for material selection, product compliance, and fire safety.

1. Why Do We Need Combustion Performance Testing?

Controlling Safety at the Source of Risks In fire accidents. A material’s combustion behavior directly determines the fire’s spread speed and hazard level:

– Some plastics (e.g., polyethylene) produce fast-moving molten drippings when burning, which may ignite combustibles below and further expand the fire.

– Materials like fabrics and foams release toxic gases (e.g., carbon monoxide, hydrogen chloride) when burning, which are the main cause of casualties in fires.

– If insulating materials inside electrical and electronic equipment burn and spread rapidly, they may cause short circuits, leading to equipment explosions.

The core goal of the Vertical and Horizontal Burning Tests is not to “destroy the material,” but to quantify the material’s combustion characteristics (e.g., combustion spread speed, afterflame time, dripping hazard) through standardized scenario simulation. This helps screen materials that meet safety standards—ensuring materials are “difficult to burn, burn slowly, and do not drip” when exposed to fire, buying valuable time for personnel evacuation and fire fighting.

2. Vertical Burning Test: Focus on “Dripping and Spreading” to Guard High-Risk Scenarios

The Vertical Burning Test mainly targets materials that are vertically installed or prone to dripping (e.g., electrical/electronic casings, component insulation sleeves, wire and cable sheaths). It simulates the combustion behavior of vertically placed materials when exposed to fire, with a focus on evaluating “combustion spread speed” and “the ignition risk of molten drippings.”

1). Core Principle: Vertical Fire Exposure, Strict Judgment of Dripping and Afterflame

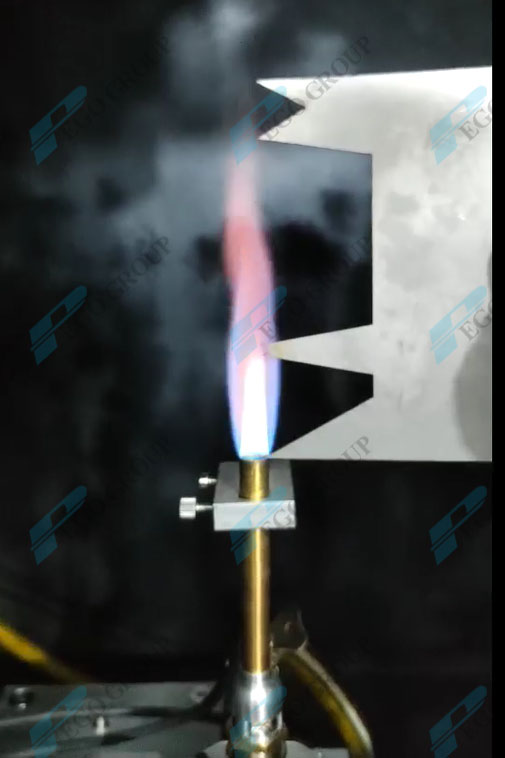

During the test, operators vertically fix the sample on a stand and ignite the lower edge of the sample with a standard flame ( a propane Bunsen burner), strictly controlling the ignition time (e.g., 10s per ignition). After removing the flame, they observe three key indicators: the “afterflame time” (the duration the sample continues to burn after the flame is removed), the “afterglow time” (the duration the sample remains glowing without a flame), and whether molten drippings ignite the absorbent cotton placed 300mm below the sample.

In simple terms, the core logic of the Vertical Burning Test is: “A material must not only be difficult to burn itself but also prevent ‘fireball-like’ drippings from igniting other objects.”

2). Key Standards: A Universal “Flame Retardancy Rating Benchmark”

Countries and regions have defined test methods and evaluation criteria for vertical burning through standards, with the most authoritative being the US UL94 (Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances) and the International Electrotechnical Commission (IEC) standards IEC 60695-11-3 and IEC 60695-11-4. Taking the most widely used “UL94 Vertical Burning Ratings” (V0/V1/V2) as an example, the evaluation criteria are shown in the table below:

| Flame Retardancy Rating | Single Ignition Time | Single Afterflame Time | Total Afterflame Time (Two Ignitions) | Do Drippings Ignite Absorbent Cotton? |

| V0 | 10s | ≤10s | ≤50s | NO |

| V1 | 10s | ≤30s | ≤250s | NO |

| V2 | 10s | ≤30s | ≤250s | YES |

Note: The test must be repeated on 5 samples. All samples must meet the requirements to be classified at the corresponding rating.

Additionally, in China’s national standard GB/T 2408-2021, the technical requirements for the Vertical Burning Test (Method B) are highly consistent with UL94, ensuring that domestic product testing aligns with international practices and meets compliance requirements for both domestic and overseas markets.

3. Horizontal Burning Test: Focus on “Spread Speed” for Low-to-Medium Risk Scenarios

The Horizontal Burning Test targets materials that are horizontally installed or have low combustion spread risks. (e.g., automotive dashboard plastics, architectural decorative fabrics, foam cushioning materials). It simulates the combustion behavior of horizontally placed materials when exposed to fire, with the core evaluation indicator being “flame spread speed”—the rate at which the flame spreads across the material surface. A slower speed means lower difficulty in fire control.

1). Core Principle: Horizontal Fire Exposure, Quantifying Spread Efficiency

During the test, operators horizontally fix the sample on a stand and ignite one end of the sample with a standard flame (propane Bunsen burner). They observe the time it takes for the flame to spread from the “ignition point” to a preset marked line, then calculate the “flame spread speed” using the formula “spread distance ÷ spread time.” A slower speed indicates better flame retardancy of the material.

Unlike the Vertical Burning Test, the Horizontal Burning Test focuses more on “whether the flame spreads rapidly” rather than “whether drippings occur”—because horizontally placed materials have a lower risk of secondary ignition from drippings, but flame spread across the surface can still cause large-scale combustion.

2). Key Standards: Clear Classification for Different Scenarios

Mainstream standards for the Horizontal Burning Test also include UL94, IEC 60695-11-3, and IEC 60695-11-4. Among these, the “UL94 HB Rating (Horizontal Burning Rating)” is the most widely used. Method A (Horizontal Burning) in China’s GB/T 2408-2021 fully aligns with the technical requirements of UL94 HB.

3). Result Evaluation

Record the time it takes for the flame to spread from the “start mark” (25mm from the ignition end) to the “end mark” (125mm from the ignition end), then calculate the spread speed. The sample is deemed qualified if the speed meets HB requirements (≤40mm/min for thickness ≤3mm, ≤75mm/min for thickness >3mm) and no drippings ignite the absorbent cotton.

4. Vertical vs. Horizontal Burning Tests

Although both belong to “material combustion performance testing,” the Vertical and Horizontal Burning Tests differ significantly in application scenarios and evaluation indicators. The selection should be based on the material’s actual installation method and fire risk level.

| Comparison Dimension | Vertical Burning Test | Horizontal Burning Test |

| Sample Placement | Vertically fixed (simulates vertical installation) | Horizontally fixed (simulates horizontal installation) |

| Core Evaluation Indicators | Afterflame time, dripping ignition, combustion height | Flame spread speed, spread distance |

| Applicable Materials | Electrical/electronic casings, insulation sleeves, cable sheaths | Automotive interiors, architectural decorative materials, foam |

| Corresponding Flame Retardancy Ratings | UL94 V0/V1/V2, GB/T 2408 Method B, IEC60695-11-4, IEC60695-11-3 | UL94 HB, GB/T 2408 Method A, IEC60695-11-4, IEC60695-11-3 |

| Fire Risk Adaptation | High risk (needs drip prevention and rapid spread prevention) | ow-to-medium risk (needs slow spread prevention) |

| Typical Application Cases | Mobile charger casings, LED driver casings | Automotive dashboard plastics, home appliance bases |

5. Conclusion: From “Passive Fire Prevention” to “Active Screening” —The Core Value of Combustion Testing

The Vertical and Horizontal Burning Tests are not simple “flame tests” but “screening benchmarks” for material safety performance. Through standardized scenario simulation, they convert “whether a material is safe” from subjective judgment to quantitative data, safeguarding product safety. To meet the needs of these two tests, Pego has launched a Horizontal and Vertical Flame Test Chamber, which can meet the standardized testing requirements for both vertical and horizontal burning. If you are interested in this equipment, please contact our team to obtain an official quotation and detailed technical parameters.