As the automotive industry accelerates toward electrification and intelligentization, automotive cables—acting as the “neural network” for power transmission and signal exchange in vehicles—directly determine the safety and functional stability of automobiles. From component contact during assembly to aging and wear during long-term use, the insulation layer of cables faces constant risks of abrasion. Once the insulation layer fails, it may cause minor issues like circuit malfunctions and functional failures, or even severe hazards such as short circuits and spontaneous combustion. Against this backdrop, the scrape abrasion has emerged as a core quality inspection device throughout the automotive industry chain, providing scientific and accurate quantitative evaluation of the wear resistance of wire insulation layers.

I Scope of Application and Testing Standardsof Scrape Abrasion Tester

Scrape abrasion test for automotive cables does not apply to all product specifications; it has clear application boundaries and standard references. According to the international standard ISO 6722-1 Road Vehicles – Single-Core Cables of Rated Voltages 60 V and 600 V – Part 1: General Requirements, abrasion test mainly targets single-core copper cables with a conductor cross-sectional area ≤ 6 mm². This specification covers most low-voltage signal wires and power wires in automobiles, which also have the highest friction risk in daily use. For cables with a cross-sectional area > 6 mm², their insulation layers are usually thicker and more robust, and they are mostly used in fixed installation scenarios, so the standard does not mandate wear resistance testing for them.

In terms of specific testing methods, ISO 6722-1 recommends two mainstream solutions: sandpaper abrasion test and scrape abrasion test. Scrape abrasion test simulates the reciprocating scratching of wires by sharp objects to evaluate the insulation layer’s resistance to sharp-edge wear. Sandpaper abrasion testing, on the other hand, simulates long-term friction between wires and rough surfaces, focusing on the insulation layer’s resistance to fatigue wear. The two methods have different focuses. In practical application, customers and suppliers need to determine which one to use based on factors like the wire’s installation location and service environment, ensuring that the testing scenario highly matches real working conditions.

II Core Structure and Technical Parameters ofScrape Abrasion Tester

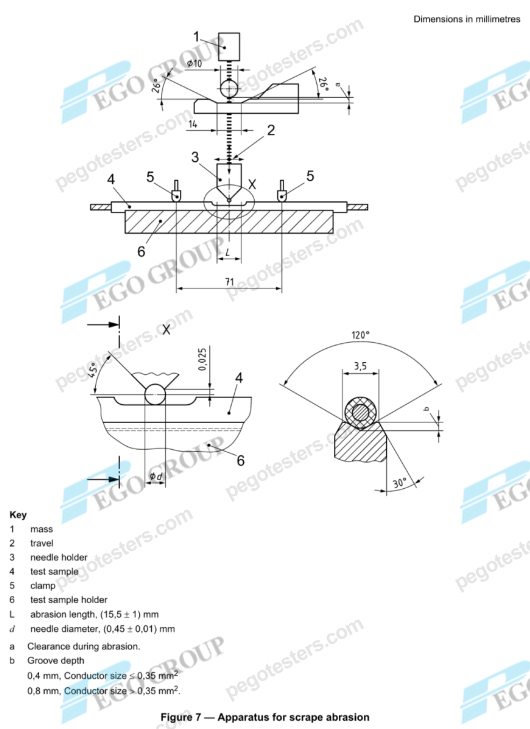

An automotive wire scrape abrasion tester that meets ISO 6722-1 must strictly comply with specifications in both structural design and technical parameters to ensure the accuracy and repeatability of test results. The equipment consists of two parts: first, a mechanical device that performs reciprocating scratching along the longitudinal axis of the wire; second, an intelligent counter that records the number of scratch cycles in real time. When the scratch needle penetrates the insulation layer and touches the conductor, the equipment immediately triggers a power-off protection mechanism and stops automatically. The number of cycles recorded at this point serves as the scratch resistance index of the wire.

To simulate scratch conditions in real usage scenarios, standards clearly define key equipment parameters with precision:

a). Scratch pin specifications: The diameter is strictly controlled at (0.45±0.01) mm. The material is polished spring steel wire that meets ISO 6931-1, which not only ensures stable scratching strength but also avoids test deviations caused by material impurities.

b). Operating parameters: The scratching frequency is set to (55±5) cycles per minute (one cycle includes one reciprocating movement). The displacement distance of the pin is (20±1) mm, and the actual wear length acting on the wire is (15.5±1) mm, ensuring uniform scratching intensity per unit time.

c). Force control: The vertical pressure applied to the wire must be precisely adjusted according to factor of coductor size. During dynamic testing, the force fluctuation must not exceed ±0.05 N.

d). Testing process: Each sample undergoes 4 parallel tests in a standard environment of (23±1)°C. After each test, the sample must be rotated 90° and moved 100 mm, and a new scratch pin must be replaced at the same time. Finally, the minimum value among the 4 results is used as the judgment basis.

This testing device not only strictly meets the wear resistance testing requirements in the international automotive wire standard ISO 6722-2006 but also fully covers a number of authoritative industry standards, including:

German standard DIN 72551.5-1991 Road Vehicles – Low-Voltage Cables – Part 5: Requirements and Tests for Single-Core Unshielded Thin-Wall PVC Insulated Low-Voltage Cables;

China’s automotive industry standard QC/T 730-2005 Thin-Wall Insulated Low-Voltage Wires for Automobiles;

JASO D611-94 Automotive Thin-Insulation Low-Voltage Cables from the Japan Automobile Standards Organization;

Requirements for automotive wire wear resistance testing in German Volkswagen’s corporate standard VW 60306.

III Application Scenarios and Industry Value

The application value of the automotive wire scratch resistance tester is reflected in multiple key links of the automotive industry chain, serving as an important support for ensuring product quality and improving industry standards.

(1) Application Scenarios Across the Industry Chain

The scrape abrasion tester holds application value across multiple key links of the automotive industry chain, acting as crucial support for ensuring product quality and enhancing industry standards. For automotive wiring harness manufacturers, it serves as a “mandatory link” in quality control—used to verify if suppliers’ wires meet procurement standards during raw material warehousing, monitor insulation extrusion process stability during production, and confirm batch quality through random sampling before delivery. For automobile manufacturers, it functions as a “screening tool” in R&D and mass production. For third-party testing institutions, it is the “technical cornerstone” for authoritative reports, enabling standardized testing per ISO/GB standards.

(2) Irreplaceable Industry Value

Strengthening the safety line: Industry statistics show that electrical faults caused by worn wire insulation account for more than 20% of total automotive faults, and about 30% of these may cause short circuits or fires. Through scratch resistance testing, substandard products can be eliminated in advance, reducing the incidence of safety accidents from the source.

Improving product reliability: Test data can guide enterprises to optimize production in reverse—for example, when the scratch resistance of a batch of wires decreases, the problem can be traced to links such as insulation material formulas and extrusion processes, promoting technical improvements. This not only extends the service life of wiring harnesses but also significantly reduces vehicle after-sales maintenance costs and improves user experience.

Promoting standard unification: The standardized control of testing processes by the equipment makes the testing data of different enterprises and institutions comparable, promoting the unification and improvement of quality standards in the industry and laying the foundation for high-quality collaborative development of the automotive industry chain.

V Conclusion: Technological Upgrades Drive the Automotive Industry Toward Higher Safety Standards

With the popularization of new energy vehicles and intelligent driving technologies, automotive cables face increasingly harsh working conditions: high-voltage wiring harnesses need to withstand higher temperatures and mechanical stress, while sensor wiring harnesses need to maintain signal stability during long-term vibration. These all place higher requirements on the scratch resistance of insulation layers. As a core device for quality evaluation, the scrape abrasion tester ability to accurately adapt to multiple standards (such as ISO, DIN, JASO, and QC/T) will directly affect the reliability of automotive electrical systems.