The article is introduce the structure, technical parameters, working principle and application of low temperature impact test device.

1. Structural Composition: Precise Construction Ensures Test Accuracy

1.1 Impact Drop Hammer System:

To meet various test requirements, the low temperature impact test device is equipped with drop hammers of multiple mass specifications, commonly including 100g and 1000g. Test personnel can flexibly select the appropriate mass of the drop hammer according to specific test standards and sample characteristics. This ensures the impact force is just right and accurately simulates the impact conditions in real usage scenarios.

1.2 Guiding Mechanism:

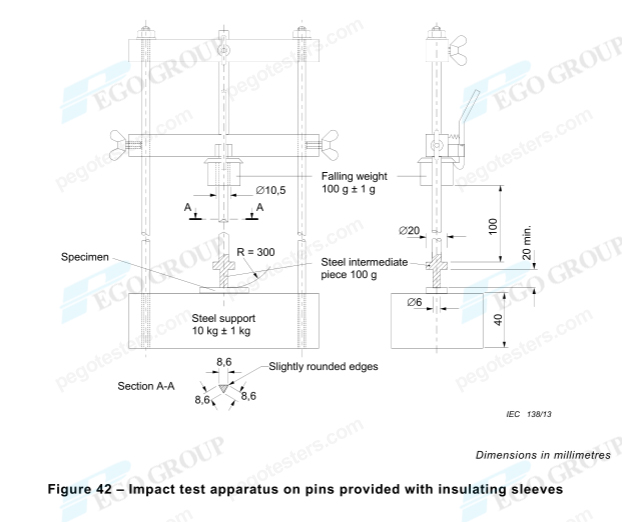

The guiding mechanism mostly adopts a triangular guiding rod design, and its edges undergo special treatment to be slightly rounded. This unique structure can effectively guide the drop hammer to fall vertically in a straight line. As a result, it largely avoids the offset or shaking of the drop hammer during the falling process, ensuring each impact precisely acts on the sample. This significantly improves the accuracy and repeatability of the impact, laying a solid foundation for the reliability of test results.

1.3 Steel Cushion Block:

The steel cushion block plays a crucial role in transmitting the impact force during the impact test. It generally has a diameter of 20mm, a spherical bottom with a radius of 300mm, and a mass of 100g. This special shape and mass configuration enable the impact force of the drop hammer to be uniformly and concentratedly transmitted to the test sample. Consequently, it simulates the impact effect in the real environment, helping test personnel more accurately evaluate the performance of the sample under low-temperature impact.

1.4 Sample Fixing Device:

The sample fixing device features high versatility and stability, and it can firmly fix various test samples, such as plugs, sockets, switches, and wires and cables. During the test, no matter how strong the impact force is, this device can ensure the sample remains stable in position. This prevents test result deviations caused by sample displacement and provides a reliable guarantee for the smooth progress of the test.

2. Technical Parameters: Precise Indicators Measure Equipment Performance

Model | PG-LTI-1 |

Working Station | 1 |

Falling weight | 100g, 1000g |

Falling impact height | 100mm |

Steel block | Φ20, bottom arc: R300, 100g |

Cool time | >24h for pin-insulating sleeves >16h for plug and socket-outlet |

Test temperature | (-15±2)℃ |

Steel support | Thickness: 40mm, Weight: 10±1KG |

Release mode | Manual, mechanical release |

Standard conform to | IEC60884-1 clauses 24.4 and 30.4, figures 27 and 42 |

3. Working Principle: A Scientific Process to Simulate Real Scenarios

Before the test begins, first place the test sample under the middle steel cushion block. Then, adjust the position of the hook frame according to the test requirements to ensure the distance between the upper end of the steel cushion block and the lower end of the weight meets the specified value. Subsequently, place the entire device on a 40mm – thick sponge rubber pad and put them together into the low-temperature chamber. Keep the sample in the low-temperature chamber for the specified time to allow the sample to fully reach the low-temperature state. This ensures that the internal structure and performance of the sample stabilize under the low-temperature environment. When the sample temperature stabilizes, release the drop hammer. The drop hammer freely falls onto the sample under the action of gravity, applying a predetermined impact force to the sample. Test personnel comprehensively evaluate the impact resistance of the sample in a low-temperature environment by observing the damage of the sample after the impact, such as whether there are cracks, deformations, fractures, etc., and whether the electrical performance changes. This provides important evidence for the quality and reliability of the product.

4. Application Areas: Guardians of Product Quality in Multiple Industries

4.1 Electronics and Electrical Appliances Industry:

In the electronics and electrical appliances field, the IEC60884-1 low-temperature impact test device plays a vital role. For commonly used electrical accessories like plugs, sockets, and switches, as well as product components such as outdoor equipment casings that are exposed to harsh environments for a long time, strict tests in the low-temperature impact test chamber can effectively evaluate their mechanical strength and impact resistance in a low-temperature environment. This helps enterprises promptly identify potential defects in the product design and manufacturing process, optimize product quality, enhance product reliability and safety in actual use, and ensure consumers can use various electronics and electrical appliances with confidence.

4.2 Automotive Parts Manufacturing Industry:

During the driving process of vehicles, especially in cold regions, their components need to withstand the dual tests of low temperature and various impacts. The test device can simulate the actual operation conditions of vehicles in cold environments and conduct low-temperature impact tests on key components such as bumpers and battery packs. Through these tests, automotive manufacturers can deeply understand the performance changes of components under low-temperature impact, discover potential safety hazards in advance, optimize component design and material selection, improve the driving safety and reliability of vehicles in cold regions, and provide consumers with safer and more reliable travel guarantees.

4.3 Aerospace Field:

Aerospace equipment faces harsh environments of extreme low temperature and complex airflow impacts during high-altitude flights. The quality and reliability of key components such as cabin door hinges and fasteners are directly related to flight safety. With the help of the low-temperature impact test device, aerospace enterprises can conduct strict low-temperature impact tests on these components, ensuring they still maintain good mechanical performance and reliability in high-altitude low-temperature environments. This is of great significance for ensuring the safe operation of aerospace equipment and promoting the development of aerospace technology.