This article elaborates on the overview, working principle, functions, technical advantages and application of the Pego IEC60065 plug torque test device.

1. Device Overview

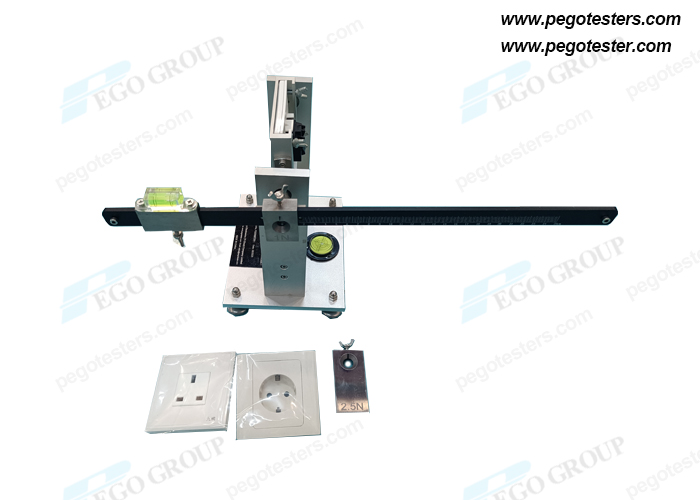

The IEC60065 plug torque test device is a professional testing equipment used to detect whether the mechanical stress generated by the plug of a plug-in device when inserting into a socket complies with safety standards. Its core purpose is to quantify the torque value to prevent the plug from exerting excessive stress on the socket, avoiding safety hazards (such as socket deformation, poor contact, or electrical failures) caused by mechanical damage.

2. Detailed Working Principle

The device simulates the mechanical stress in actual use scenarios through the following mechanisms:

2.1 Core of Mechanical Simulation:

Taking the horizontal axis 8 mm behind the mating surface of the output socket and passing through the centerline of the socket hole as the fulcrum, the balance arm acts around this axis to accurately replicate the torque effect when the plug is inserted.

2.2 Weight Apply:

When the plug is inserted into the socket, place the weight on the balance arm, and move the weight to keep the arm balance, then calculate the torque value. The max. Torque is 2.5N/m.

3. Core Functions and Technical Advantages

Functional Module | Technical Details and Advantages |

Standards Compliance | 1. Compatible with international standards (IEC60065) and domestic standards (GB2099.1, GB4706, etc.), ensuring test results are globally recognized. |

Multi-Standard Adaptability | Supports socket fixtures for GB (China), BS (UK), UL (US), Australian three-round holes, and other regional standards, adapting to testing requirements in major global markets. |

High-Precision Torque Measurement | Achieves stepwise torque adjustment through weight combinations (e.g. 1N, 2.5N), ensuring accuracy and repeatability of test data. |

Structural Design Optimization | 1. The balance arm extends up to 250 mm, featuring high sensitivity to capture subtle torque changes; |

4.Applic ation Scenarios and Industry Use Cases

4.1 Product R&D Stage: Assists engineers in optimizing plug structure design to avoid socket adaptability issues caused by excessive torque.

4.2 Production Quality Control: Conducts batch testing of mechanical stress on finished plugs to ensure compliance with safety standards, reducing post-sales risks of complaints due to socket damage.

4.3 Third-Party Testing Institutions: Provides compliance certification testing for home appliances and electronic devices (e.g., chargers, small household appliances, communication equipment), facilitating product access to global markets.